Leading Non-Rising Stem Gate Valve Supplier for Industrial Applications: Quality and Reliability

2025-12-30

In the demanding world of industrial applications, reliability isn't just a feature—it's the foundation of seamless operations. When it comes to leading non-rising stem gate valves, the choice of supplier can make all the difference in ensuring durability, performance, and safety. At DRIFCO, we've dedicated ourselves to engineering solutions that not only meet but exceed these rigorous standards. Our commitment to quality and innovation sets a new benchmark in the industry, empowering businesses to tackle the toughest challenges with confidence. As we delve into the intricacies of these vital components, discover how DRIFCO's expertise transforms everyday operations into seamless successes. From cutting-edge designs to unparalleled service, get ready to explore what makes us the go-to partner for industrial valve solutions. Dive in to learn more about the game-changing benefits and why forward-thinking engineers trust us to deliver peak performance.

Expertise in Non-Rising Stem Gate Valve Design for Industrial Use

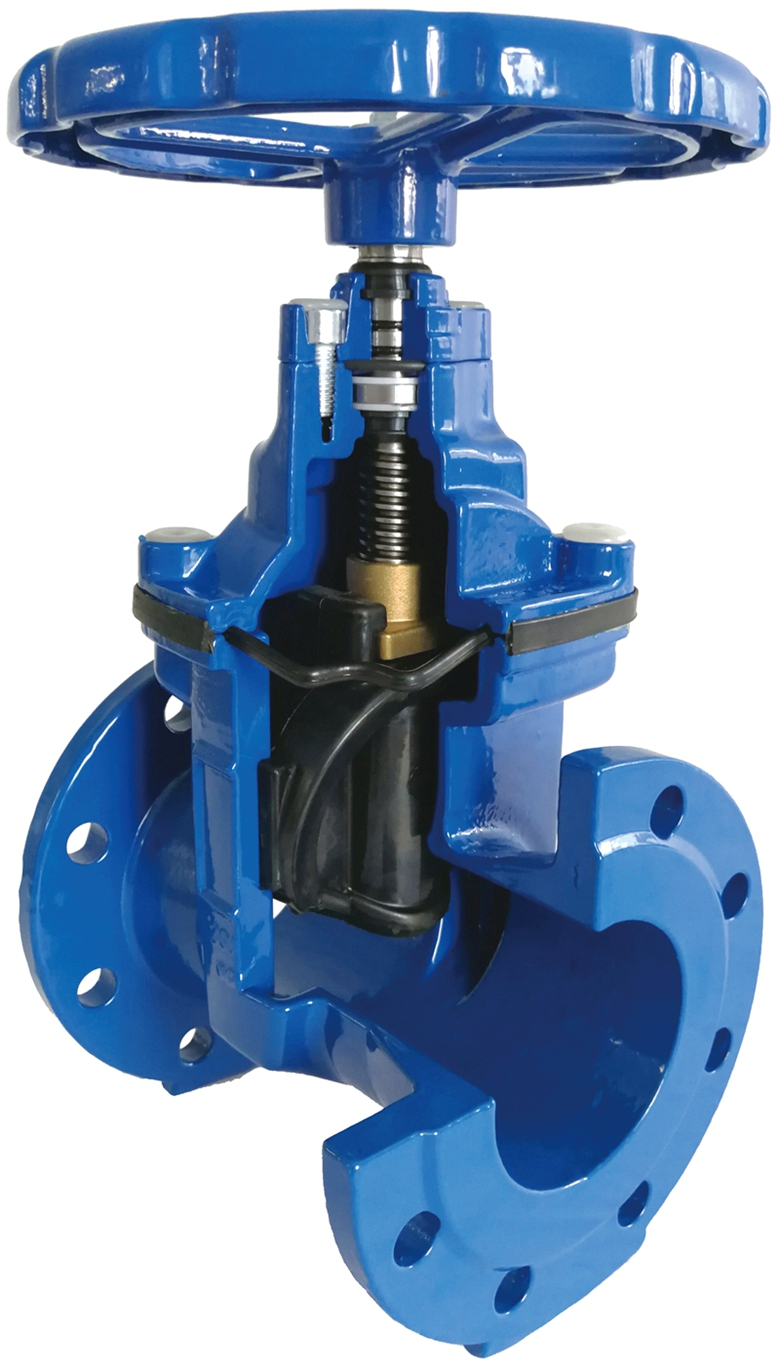

In industrial applications, non-rising stem gate valves stand out for their compact design and reliable performance, where expertise in their construction ensures optimal flow control and minimal maintenance. Unlike rising stem valves that extend upward during operation, these valves keep the stem stationary while the gate moves, making them ideal for confined spaces or systems where vertical clearance is limited. This design often incorporates durable materials like stainless steel or bronze, tailored to resist corrosion and wear in harsh environments such as chemical processing or water treatment facilities. By focusing on precise tolerances and smooth actuation, engineers can enhance sealing efficiency and reduce the risk of leaks, a critical factor in maintaining operational safety and efficiency across various industries.

Developing such valves requires a deep understanding of mechanical engineering and fluid dynamics, as factors like pressure ratings, temperature ranges, and media compatibility must be carefully balanced. For instance, in oil and gas pipelines or power generation plants, non-rising stem gate valves are often designed with robust gaskets and stem packing to withstand high pressures and prevent fugitive emissions. Expertise also involves customizing features like handwheel or gear operators for easy manual control, or integrating with automated systems for remote monitoring and shutdown. By leveraging advanced simulation tools and rigorous testing, designers can predict performance under stress and refine the valve's geometry to minimize pressure drops and ensure long-term durability, thereby avoiding costly downtime and failures in critical processes.

Ultimately, specialization in this area goes beyond standard specifications, emphasizing innovation to meet evolving industrial demands. This might include incorporating smart sensors for real-time diagnostics or using coatings to enhance resistance to abrasive slurries. By prioritizing user-centric design and adhering to international standards like API or ANSI, experts can deliver valves that not only perform reliably but also offer ease of installation and maintenance, setting them apart in competitive markets. Such tailored solutions help industries optimize their operations, reduce environmental impact, and ensure compliance with safety regulations, making non-rising stem gate valves a cornerstone of modern industrial infrastructure.

Commitment to Unmatched Quality and Durability in Valve Manufacturing

We stand by a promise of quality in valve manufacturing that goes beyond industry standards. It starts with rigorous material selection—using corrosion-resistant alloys and high-grade steel that can withstand extreme pressures and temperatures. Every batch is tested for integrity before production even begins.

Our durability focus extends to precision engineering. Each valve is crafted with tight tolerances and advanced sealing technologies, ensuring leak-free performance in demanding environments like oil refineries or chemical plants. We don't just make valves; we build reliability into every component.

This commitment isn't a one-time effort. We continuously refine our processes based on real-world feedback, guaranteeing that our valves last longer and require less maintenance. It's why customers trust us for critical applications where failure isn't an option.

Reliable Performance Solutions for Diverse Industrial Settings

In the industrial realm, reliability isn't just a checkbox—it's the backbone of operational success. Diverse settings, from chemical plants to manufacturing floors, demand tailored solutions that can withstand harsh environments and fluctuating demands. We focus on delivering performance that's built to last, ensuring minimal downtime and maximizing productivity through robust engineering and continuous monitoring, so your operations run smoothly day in and day out.

Every industry faces unique challenges, whether it's high temperatures in metal processing or precision requirements in electronics assembly. Our solutions are designed with this diversity in mind, offering adaptable systems that can be fine-tuned to specific needs. By integrating advanced technologies like real-time data analytics and predictive maintenance, we provide not just equipment but a comprehensive approach to sustaining peak performance across varied applications.

Beyond the hardware, we emphasize partnership and support, understanding that reliable performance hinges on more than just initial installation. Our team works closely with clients to develop long-term strategies, ensuring that solutions evolve with changing industrial landscapes. This commitment to customization and ongoing optimization sets us apart, helping businesses thrive in competitive markets by delivering consistent, dependable results wherever they operate.

Innovation in Valve Technology for Enhanced Operational Efficiency

Innovation in valve technology is revolutionizing how industries achieve operational efficiency, moving beyond traditional designs to smarter, more responsive solutions. Modern advancements focus on materials that withstand harsh environments, such as corrosion-resistant alloys for chemical processing or high-temperature ceramics in energy sectors, reducing maintenance downtime and extending equipment lifespan. By integrating predictive analytics and IoT sensors, these valves can monitor performance in real-time, allowing for proactive adjustments that optimize flow rates and minimize energy consumption. This shift not only enhances reliability but also drives cost savings and sustainability, making operations leaner and more competitive.

Another key area of innovation lies in the development of automated and intelligent valve systems. Smart valves equipped with embedded software and control algorithms can autonomously adjust to changing conditions, such as pressure fluctuations or temperature variations, without manual intervention. For instance, in water management or oil and gas pipelines, these systems ensure precise regulation and leak detection, preventing costly spills and disruptions. This automation streamlines workflows, reduces human error, and supports continuous operation, ultimately boosting overall efficiency in complex industrial networks.

Looking ahead, innovations like 3D printing and modular designs are further transforming valve technology by enabling customized solutions tailored to specific operational needs. Additive manufacturing allows for rapid prototyping and production of complex geometries that improve performance, while modular components simplify upgrades and repairs, cutting down on installation time. Combined with adaptive control mechanisms, these advancements pave the way for more resilient and efficient industrial processes, where valves act as integral, flexible parts of a connected ecosystem.

Customer-Focused Support and Customization Options Available

At the heart of our approach lies a genuine commitment to your unique needs. We don't just offer generic solutions; instead, our team takes the time to understand your specific challenges and goals. Whether you're looking to streamline operations or enhance user engagement, we provide tailored support that evolves with your business, ensuring you always feel prioritized and heard.

Our customization options are designed to adapt effortlessly to your workflow. You can modify features, integrate third-party tools, or even request bespoke developments that align perfectly with your vision. This flexibility means you're not confined to a rigid framework—instead, you get a solution that grows and changes as you do, making it a true partner in your success.

Imagine having a dedicated expert who not only solves issues but proactively suggests improvements based on your usage patterns. That's the level of personalized service we aim for, combining responsive assistance with forward-thinking strategies to keep you ahead of the curve. It's all about creating an experience that feels uniquely yours, every step of the way.

Ensuring Consistent Reliability Across Global Supply Chains

In today's interconnected world, supply chains stretch across continents, weaving a complex network of manufacturers, logistics providers, and distributors. Ensuring consistency in this vast ecosystem requires more than just robust contracts; it demands a proactive approach to visibility and collaboration. Companies are increasingly investing in real-time tracking technologies and data analytics to monitor every link, from raw material sourcing to final delivery. This granular insight helps identify bottlenecks early, allowing for swift adjustments that maintain reliability even amid unforeseen disruptions like geopolitical tensions or natural disasters.

Building resilient supply chains also hinges on fostering strong partnerships with key stakeholders. Rather than viewing suppliers as mere vendors, forward-thinking organizations cultivate long-term relationships based on mutual trust and shared goals. Regular audits, joint risk assessments, and collaborative contingency planning become standard practice. By aligning interests and creating redundancy through strategic diversification, businesses can mitigate single-point failures and ensure that reliability isn't just a promise but a consistent reality, regardless of geographic or market fluctuations.

Moreover, integrating sustainability into supply chain operations adds another layer of reliability by future-proofing the network. Ethical sourcing, environmental compliance, and social accountability reduce the risk of regulatory penalties or reputational damage. When companies prioritize these aspects, they not only enhance operational stability but also build consumer trust, which in turn strengthens the overall chain's dependability. This holistic approach transforms supply chains from fragile threads into resilient webs, capable of withstanding shocks while delivering value consistently.

FAQ

A leading supplier stands out through robust engineering, consistent quality control, and a proven track record in industrial applications. They invest in research and development, ensuring valves meet stringent standards and perform reliably under extreme conditions.

Non-rising stem gate valves save space and are ideal for confined areas, as the stem doesn't extend outward during operation. They provide tight shut-off and durability, reducing maintenance needs in harsh environments like chemical plants or water treatment facilities.

Top features include corrosion-resistant materials like stainless steel or bronze, precise machining for leak-free performance, and designs that handle high pressures and temperatures. Look for certifications and long-term testing data to gauge reliability.

Oil and gas, power generation, and manufacturing sectors rely on them for their robustness and efficiency. They're favored in applications requiring frequent cycling or where space constraints exist, ensuring operational continuity and safety.

Reliability minimizes downtime and repair costs, leading to significant savings over time. Durable valves reduce the risk of failures that can disrupt production or cause safety hazards, making them a cost-effective choice despite higher initial investment.

Evaluate supplier reputation, product certifications, customization options, and after-sales support. Check for real-world case studies or client testimonials to ensure they deliver consistent performance and meet specific industrial needs.

Regular inspections for wear, proper lubrication, and avoiding over-tightening during operation can prolong valve life. Follow manufacturer guidelines and schedule preventive maintenance to prevent issues like stem corrosion or seat damage.

Conclusion

As a leading supplier in the industrial valve market, this company excels in non-rising stem gate valve design, tailored specifically for demanding industrial applications. With deep expertise in engineering and manufacturing, it offers valves that prioritize durability and precision, ensuring optimal performance across diverse settings from chemical plants to water treatment facilities. By integrating innovation into valve technology, the company enhances operational efficiency, reducing downtime and maintenance costs while maintaining robust functionality. This focus on quality and reliability is complemented by a commitment to customer-centric support, providing customization options that adapt to unique operational needs.

The company's dedication extends beyond production to ensure consistent reliability throughout global supply chains, fostering trust with clients worldwide. Through continuous improvement and rigorous testing, it delivers solutions that meet stringent industry standards, reinforcing its reputation for unmatched quality. By blending innovative design with a customer-focused approach, this supplier not only addresses immediate industrial challenges but also sets a benchmark for long-term value and dependability in the valve industry.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com