Top UL FM Gate Valve Suppliers: Innovative Solutions for Safe and Reliable Industrial Flow Control

2025-12-22

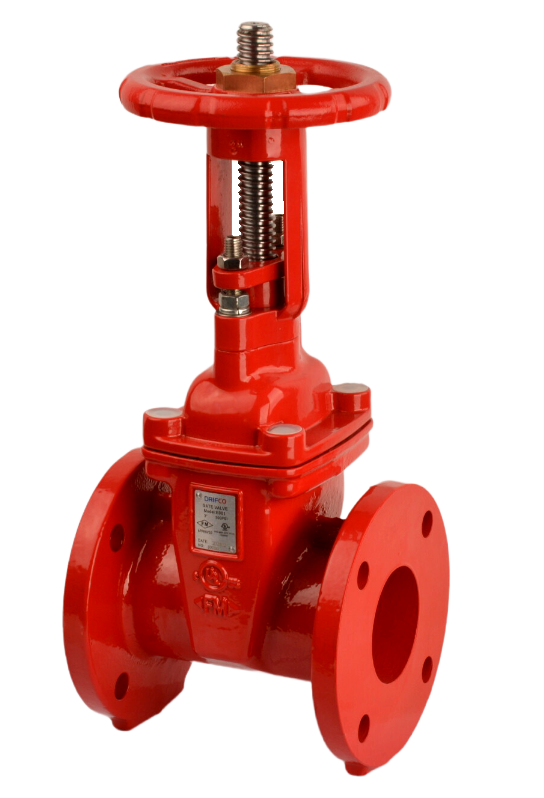

In the world of industrial flow control, safety and reliability are non-negotiable. As industries evolve, the demand for high-performance UL-listed gate valves continues to rise, driving innovation among top suppliers. At the forefront of this movement is DRIFCO, a name synonymous with cutting-edge solutions that meet stringent safety standards. This blog explores the leading UL FM gate valve suppliers, showcasing how they deliver robust, dependable products for critical applications. From advanced materials to precision engineering, discover what sets these innovators apart. With DRIFCO leading the charge, we'll dive into how these suppliers are redefining flow control to enhance operational efficiency and minimize risks. Ready to learn more about the game-changers in industrial valve technology? Let's begin.

Leading UL FM Gate Valve Manufacturers for Industrial Safety

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

Innovative Flow Control Solutions: Enhancing Reliability in Critical Systems

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

In today's complex industrial and operational environments, the stability of fluid and gas systems—be it in aerospace, energy, or healthcare—depends heavily on advanced flow control. By leveraging innovations like smart valves that adjust in real-time to fluctuating pressures, and predictive maintenance through AI-driven sensors, these solutions proactively mitigate risks such as leaks or blockages. This not only extends equipment lifespan but also ensures uninterrupted processes, making systems more resilient against unexpected disruptions.

Beyond mere regulation, cutting-edge flow control integrates adaptive algorithms and modular designs to offer customizable reliability. For instance, in critical industries like pharmaceutical manufacturing or nuclear power, where minute variations can compromise safety, these innovations provide precise, repeatable control. By moving away from traditional one-size-fits-all approaches, they enable tailored configurations that enhance performance while reducing operational costs, setting a new benchmark for dependability in high-stakes applications.

Ultimately, the true value of innovative flow control lies in its synergy with broader system architectures. Through seamless integration with IoT platforms and data analytics, these solutions don't just react to issues but anticipate them, fostering a proactive reliability culture. This holistic approach ensures that critical systems not only meet stringent standards but exceed them, delivering consistent, high-quality outcomes even under the most demanding conditions.

Key Suppliers of UL FM Certified Gate Valves for Hazardous Environments

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

In today's complex industrial and operational environments, the stability of fluid and gas systems—be it in aerospace, energy, or healthcare—depends heavily on advanced flow control. By leveraging innovations like smart valves that adjust in real-time to fluctuating pressures, and predictive maintenance through AI-driven sensors, these solutions proactively mitigate risks such as leaks or blockages. This not only extends equipment lifespan but also ensures uninterrupted processes, making systems more resilient against unexpected disruptions.

Beyond mere regulation, cutting-edge flow control integrates adaptive algorithms and modular designs to offer customizable reliability. For instance, in critical industries like pharmaceutical manufacturing or nuclear power, where minute variations can compromise safety, these innovations provide precise, repeatable control. By moving away from traditional one-size-fits-all approaches, they enable tailored configurations that enhance performance while reducing operational costs, setting a new benchmark for dependability in high-stakes applications.

Ultimately, the true value of innovative flow control lies in its synergy with broader system architectures. Through seamless integration with IoT platforms and data analytics, these solutions don't just react to issues but anticipate them, fostering a proactive reliability culture. This holistic approach ensures that critical systems not only meet stringent standards but exceed them, delivering consistent, high-quality outcomes even under the most demanding conditions.

Identifying reliable suppliers for UL FM certified gate valves in hazardous environments can be a game-changer for safety and compliance. These suppliers often stand out not just for their certifications but for their specialized expertise in handling volatile applications, where even minor valve failures could lead to significant safety risks. For instance, companies like ValvTechnologies and DeZURIK have built reputations by offering robust, field-tested solutions specifically engineered for oil refineries, chemical plants, and offshore installations, ensuring that their valves meet the stringent demands of these high-stakes settings without compromising on durability or ease of maintenance.

What sets top-tier suppliers apart is their commitment to innovation beyond basic compliance. Firms such as Flowserve and Crane Co. invest heavily in R&D to develop gate valves with enhanced sealing technologies and corrosion-resistant materials, tailored for harsh environments like those with flammable gases or corrosive liquids. They often provide comprehensive support, including detailed application guidance and custom engineering services, helping clients navigate complex regulatory landscapes while optimizing performance and longevity. This proactive approach not only minimizes downtime but also reduces long-term operational costs, making them preferred partners in industries where reliability is non-negotiable.

In a market crowded with generic options, discerning buyers should look for suppliers that offer transparent traceability and rigorous testing protocols. Companies like Emerson and ITT Engineered Valves, for example, emphasize full documentation and third-party audits to verify their UL FM certifications, giving clients peace of mind. Additionally, these leaders frequently engage in industry collaborations to stay ahead of emerging safety standards, ensuring their products adapt to evolving hazards. By prioritizing such suppliers, businesses can secure gate valves that not only meet but exceed safety benchmarks, fostering a culture of proactive risk management in hazardous environments.

Advanced Gate Valve Technologies: Meeting Modern Industrial Standards

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

In today's complex industrial and operational environments, the stability of fluid and gas systems—be it in aerospace, energy, or healthcare—depends heavily on advanced flow control. By leveraging innovations like smart valves that adjust in real-time to fluctuating pressures, and predictive maintenance through AI-driven sensors, these solutions proactively mitigate risks such as leaks or blockages. This not only extends equipment lifespan but also ensures uninterrupted processes, making systems more resilient against unexpected disruptions.

Beyond mere regulation, cutting-edge flow control integrates adaptive algorithms and modular designs to offer customizable reliability. For instance, in critical industries like pharmaceutical manufacturing or nuclear power, where minute variations can compromise safety, these innovations provide precise, repeatable control. By moving away from traditional one-size-fits-all approaches, they enable tailored configurations that enhance performance while reducing operational costs, setting a new benchmark for dependability in high-stakes applications.

Ultimately, the true value of innovative flow control lies in its synergy with broader system architectures. Through seamless integration with IoT platforms and data analytics, these solutions don't just react to issues but anticipate them, fostering a proactive reliability culture. This holistic approach ensures that critical systems not only meet stringent standards but exceed them, delivering consistent, high-quality outcomes even under the most demanding conditions.

Identifying reliable suppliers for UL FM certified gate valves in hazardous environments can be a game-changer for safety and compliance. These suppliers often stand out not just for their certifications but for their specialized expertise in handling volatile applications, where even minor valve failures could lead to significant safety risks. For instance, companies like ValvTechnologies and DeZURIK have built reputations by offering robust, field-tested solutions specifically engineered for oil refineries, chemical plants, and offshore installations, ensuring that their valves meet the stringent demands of these high-stakes settings without compromising on durability or ease of maintenance.

What sets top-tier suppliers apart is their commitment to innovation beyond basic compliance. Firms such as Flowserve and Crane Co. invest heavily in R&D to develop gate valves with enhanced sealing technologies and corrosion-resistant materials, tailored for harsh environments like those with flammable gases or corrosive liquids. They often provide comprehensive support, including detailed application guidance and custom engineering services, helping clients navigate complex regulatory landscapes while optimizing performance and longevity. This proactive approach not only minimizes downtime but also reduces long-term operational costs, making them preferred partners in industries where reliability is non-negotiable.

In a market crowded with generic options, discerning buyers should look for suppliers that offer transparent traceability and rigorous testing protocols. Companies like Emerson and ITT Engineered Valves, for example, emphasize full documentation and third-party audits to verify their UL FM certifications, giving clients peace of mind. Additionally, these leaders frequently engage in industry collaborations to stay ahead of emerging safety standards, ensuring their products adapt to evolving hazards. By prioritizing such suppliers, businesses can secure gate valves that not only meet but exceed safety benchmarks, fostering a culture of proactive risk management in hazardous environments.

Advanced Gate Valve Technologies: Meeting Modern Industrial StandardsAdvanced Gate Valve Technologies: Meeting Modern Industrial Standards

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

In today's complex industrial and operational environments, the stability of fluid and gas systems—be it in aerospace, energy, or healthcare—depends heavily on advanced flow control. By leveraging innovations like smart valves that adjust in real-time to fluctuating pressures, and predictive maintenance through AI-driven sensors, these solutions proactively mitigate risks such as leaks or blockages. This not only extends equipment lifespan but also ensures uninterrupted processes, making systems more resilient against unexpected disruptions.

Beyond mere regulation, cutting-edge flow control integrates adaptive algorithms and modular designs to offer customizable reliability. For instance, in critical industries like pharmaceutical manufacturing or nuclear power, where minute variations can compromise safety, these innovations provide precise, repeatable control. By moving away from traditional one-size-fits-all approaches, they enable tailored configurations that enhance performance while reducing operational costs, setting a new benchmark for dependability in high-stakes applications.

Ultimately, the true value of innovative flow control lies in its synergy with broader system architectures. Through seamless integration with IoT platforms and data analytics, these solutions don't just react to issues but anticipate them, fostering a proactive reliability culture. This holistic approach ensures that critical systems not only meet stringent standards but exceed them, delivering consistent, high-quality outcomes even under the most demanding conditions.

Identifying reliable suppliers for UL FM certified gate valves in hazardous environments can be a game-changer for safety and compliance. These suppliers often stand out not just for their certifications but for their specialized expertise in handling volatile applications, where even minor valve failures could lead to significant safety risks. For instance, companies like ValvTechnologies and DeZURIK have built reputations by offering robust, field-tested solutions specifically engineered for oil refineries, chemical plants, and offshore installations, ensuring that their valves meet the stringent demands of these high-stakes settings without compromising on durability or ease of maintenance.

What sets top-tier suppliers apart is their commitment to innovation beyond basic compliance. Firms such as Flowserve and Crane Co. invest heavily in R&D to develop gate valves with enhanced sealing technologies and corrosion-resistant materials, tailored for harsh environments like those with flammable gases or corrosive liquids. They often provide comprehensive support, including detailed application guidance and custom engineering services, helping clients navigate complex regulatory landscapes while optimizing performance and longevity. This proactive approach not only minimizes downtime but also reduces long-term operational costs, making them preferred partners in industries where reliability is non-negotiable.

In a market crowded with generic options, discerning buyers should look for suppliers that offer transparent traceability and rigorous testing protocols. Companies like Emerson and ITT Engineered Valves, for example, emphasize full documentation and third-party audits to verify their UL FM certifications, giving clients peace of mind. Additionally, these leaders frequently engage in industry collaborations to stay ahead of emerging safety standards, ensuring their products adapt to evolving hazards. By prioritizing such suppliers, businesses can secure gate valves that not only meet but exceed safety benchmarks, fostering a culture of proactive risk management in hazardous environments.

Advanced Gate Valve Technologies: Meeting Modern Industrial StandardsIn today's demanding industrial sectors, gate valves are evolving beyond basic shut-off devices to incorporate advanced technologies that directly address modern performance and safety requirements. Cutting-edge designs now feature improved sealing mechanisms, such as flexible or pressure-energized seals, which significantly reduce leakage and enhance reliability in high-pressure applications. These innovations are not just incremental upgrades; they represent a shift toward more robust solutions that can withstand extreme conditions while minimizing maintenance needs, helping industries comply with stringent environmental and operational standards.

Furthermore, the integration of smart technologies has transformed gate valves into intelligent components within broader industrial systems. Embedded sensors and actuators allow for real-time monitoring of flow rates, pressure differentials, and valve position, facilitating predictive maintenance and reducing downtime. This connectivity, often part of Industrial Internet of Things (IIoT) frameworks, enables seamless data exchange with control systems, optimizing processes and ensuring adherence to efficiency benchmarks that define contemporary industrial operations.

Additionally, advancements in materials science play a crucial role in meeting modern standards, with the use of corrosion-resistant alloys and composite materials extending valve lifespan in harsh environments like chemical processing or offshore oil extraction. This focus on durability not only improves operational longevity but also supports sustainability goals by reducing waste and resource consumption, making advanced gate valves a key enabler for industries striving to balance productivity with environmental responsibility.

Selecting the Right UL FM Gate Valve Supplier for Optimal Performance

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

In today's complex industrial and operational environments, the stability of fluid and gas systems—be it in aerospace, energy, or healthcare—depends heavily on advanced flow control. By leveraging innovations like smart valves that adjust in real-time to fluctuating pressures, and predictive maintenance through AI-driven sensors, these solutions proactively mitigate risks such as leaks or blockages. This not only extends equipment lifespan but also ensures uninterrupted processes, making systems more resilient against unexpected disruptions.

Beyond mere regulation, cutting-edge flow control integrates adaptive algorithms and modular designs to offer customizable reliability. For instance, in critical industries like pharmaceutical manufacturing or nuclear power, where minute variations can compromise safety, these innovations provide precise, repeatable control. By moving away from traditional one-size-fits-all approaches, they enable tailored configurations that enhance performance while reducing operational costs, setting a new benchmark for dependability in high-stakes applications.

Ultimately, the true value of innovative flow control lies in its synergy with broader system architectures. Through seamless integration with IoT platforms and data analytics, these solutions don't just react to issues but anticipate them, fostering a proactive reliability culture. This holistic approach ensures that critical systems not only meet stringent standards but exceed them, delivering consistent, high-quality outcomes even under the most demanding conditions.

Identifying reliable suppliers for UL FM certified gate valves in hazardous environments can be a game-changer for safety and compliance. These suppliers often stand out not just for their certifications but for their specialized expertise in handling volatile applications, where even minor valve failures could lead to significant safety risks. For instance, companies like ValvTechnologies and DeZURIK have built reputations by offering robust, field-tested solutions specifically engineered for oil refineries, chemical plants, and offshore installations, ensuring that their valves meet the stringent demands of these high-stakes settings without compromising on durability or ease of maintenance.

What sets top-tier suppliers apart is their commitment to innovation beyond basic compliance. Firms such as Flowserve and Crane Co. invest heavily in R&D to develop gate valves with enhanced sealing technologies and corrosion-resistant materials, tailored for harsh environments like those with flammable gases or corrosive liquids. They often provide comprehensive support, including detailed application guidance and custom engineering services, helping clients navigate complex regulatory landscapes while optimizing performance and longevity. This proactive approach not only minimizes downtime but also reduces long-term operational costs, making them preferred partners in industries where reliability is non-negotiable.

In a market crowded with generic options, discerning buyers should look for suppliers that offer transparent traceability and rigorous testing protocols. Companies like Emerson and ITT Engineered Valves, for example, emphasize full documentation and third-party audits to verify their UL FM certifications, giving clients peace of mind. Additionally, these leaders frequently engage in industry collaborations to stay ahead of emerging safety standards, ensuring their products adapt to evolving hazards. By prioritizing such suppliers, businesses can secure gate valves that not only meet but exceed safety benchmarks, fostering a culture of proactive risk management in hazardous environments.

Advanced Gate Valve Technologies: Meeting Modern Industrial StandardsIn today's demanding industrial sectors, gate valves are evolving beyond basic shut-off devices to incorporate advanced technologies that directly address modern performance and safety requirements. Cutting-edge designs now feature improved sealing mechanisms, such as flexible or pressure-energized seals, which significantly reduce leakage and enhance reliability in high-pressure applications. These innovations are not just incremental upgrades; they represent a shift toward more robust solutions that can withstand extreme conditions while minimizing maintenance needs, helping industries comply with stringent environmental and operational standards.

Furthermore, the integration of smart technologies has transformed gate valves into intelligent components within broader industrial systems. Embedded sensors and actuators allow for real-time monitoring of flow rates, pressure differentials, and valve position, facilitating predictive maintenance and reducing downtime. This connectivity, often part of Industrial Internet of Things (IIoT) frameworks, enables seamless data exchange with control systems, optimizing processes and ensuring adherence to efficiency benchmarks that define contemporary industrial operations.

Additionally, advancements in materials science play a crucial role in meeting modern standards, with the use of corrosion-resistant alloys and composite materials extending valve lifespan in harsh environments like chemical processing or offshore oil extraction. This focus on durability not only improves operational longevity but also supports sustainability goals by reducing waste and resource consumption, making advanced gate valves a key enabler for industries striving to balance productivity with environmental responsibility.

When it comes to choosing a UL FM gate valve supplier, the devil is often in the details. Beyond just checking for the required certifications, savvy buyers dig deeper into the supplier's manufacturing processes, quality control measures, and material sourcing. A supplier that offers custom valve solutions tailored to specific operational needs—whether for fire protection systems in high-rise buildings or industrial applications—can provide significant long-term benefits. Look for suppliers who conduct rigorous testing under real-world conditions, as this ensures the valves will perform reliably in emergencies, potentially saving lives and property. Don't just settle for a vendor; opt for a partner with a proven track record in delivering durable, compliant products.

In today's competitive market, selecting the right UL FM gate valve supplier isn't just about ticking boxes—it's about future-proofing your systems. Consider suppliers who invest in research and development, bringing innovations like enhanced corrosion resistance or smoother operation to their valve designs. A standout supplier often provides comprehensive support, including detailed installation guides, maintenance training, and responsive customer service. This holistic approach can reduce downtime, lower total cost of ownership, and ensure seamless integration with your existing infrastructure. By prioritizing suppliers who go above and beyond, you gain not just a product but a strategic advantage in safety and efficiency.

Ultimately, the optimal performance of UL FM gate valves hinges on a supplier's commitment to excellence and adaptability. Seek out suppliers who actively engage with industry standards bodies and continuously update their practices to meet evolving regulations. Customer reviews and case studies can offer valuable insights into a supplier's real-world impact, revealing how their valves perform under pressure. A reliable supplier should also have transparent communication channels, allowing for quick resolution of any issues that arise. Choosing wisely means aligning with a supplier whose values and capabilities mirror your own high standards, ensuring peace of mind and superior system performance for years to come.

Future Trends in Industrial Valve Solutions: Safety and Efficiency Focus

When it comes to safeguarding industrial operations, reliable gate valves certified by UL and FM are non-negotiable. These certifications ensure the valves meet rigorous safety and performance standards, crucial for preventing leaks, controlling flow, and protecting against fire hazards in demanding environments.

Beyond just certifications, leading manufacturers like FloMatic and SafeFlow Industries stand out by offering customizable solutions tailored to specific industrial needs, such as high-temperature resistance or corrosive fluid handling. Their commitment to innovation includes integrating smart monitoring systems that enhance preventive maintenance and operational efficiency, setting them apart from competitors.

In summary, the top UL FM gate valve providers not only deliver certified products but also drive industry advancements through quality and adaptability, making them essential for robust industrial safety frameworks.

In today's complex industrial and operational environments, the stability of fluid and gas systems—be it in aerospace, energy, or healthcare—depends heavily on advanced flow control. By leveraging innovations like smart valves that adjust in real-time to fluctuating pressures, and predictive maintenance through AI-driven sensors, these solutions proactively mitigate risks such as leaks or blockages. This not only extends equipment lifespan but also ensures uninterrupted processes, making systems more resilient against unexpected disruptions.

Beyond mere regulation, cutting-edge flow control integrates adaptive algorithms and modular designs to offer customizable reliability. For instance, in critical industries like pharmaceutical manufacturing or nuclear power, where minute variations can compromise safety, these innovations provide precise, repeatable control. By moving away from traditional one-size-fits-all approaches, they enable tailored configurations that enhance performance while reducing operational costs, setting a new benchmark for dependability in high-stakes applications.

Ultimately, the true value of innovative flow control lies in its synergy with broader system architectures. Through seamless integration with IoT platforms and data analytics, these solutions don't just react to issues but anticipate them, fostering a proactive reliability culture. This holistic approach ensures that critical systems not only meet stringent standards but exceed them, delivering consistent, high-quality outcomes even under the most demanding conditions.

Identifying reliable suppliers for UL FM certified gate valves in hazardous environments can be a game-changer for safety and compliance. These suppliers often stand out not just for their certifications but for their specialized expertise in handling volatile applications, where even minor valve failures could lead to significant safety risks. For instance, companies like ValvTechnologies and DeZURIK have built reputations by offering robust, field-tested solutions specifically engineered for oil refineries, chemical plants, and offshore installations, ensuring that their valves meet the stringent demands of these high-stakes settings without compromising on durability or ease of maintenance.

What sets top-tier suppliers apart is their commitment to innovation beyond basic compliance. Firms such as Flowserve and Crane Co. invest heavily in R&D to develop gate valves with enhanced sealing technologies and corrosion-resistant materials, tailored for harsh environments like those with flammable gases or corrosive liquids. They often provide comprehensive support, including detailed application guidance and custom engineering services, helping clients navigate complex regulatory landscapes while optimizing performance and longevity. This proactive approach not only minimizes downtime but also reduces long-term operational costs, making them preferred partners in industries where reliability is non-negotiable.

In a market crowded with generic options, discerning buyers should look for suppliers that offer transparent traceability and rigorous testing protocols. Companies like Emerson and ITT Engineered Valves, for example, emphasize full documentation and third-party audits to verify their UL FM certifications, giving clients peace of mind. Additionally, these leaders frequently engage in industry collaborations to stay ahead of emerging safety standards, ensuring their products adapt to evolving hazards. By prioritizing such suppliers, businesses can secure gate valves that not only meet but exceed safety benchmarks, fostering a culture of proactive risk management in hazardous environments.

Advanced Gate Valve Technologies: Meeting Modern Industrial StandardsIn today's demanding industrial sectors, gate valves are evolving beyond basic shut-off devices to incorporate advanced technologies that directly address modern performance and safety requirements. Cutting-edge designs now feature improved sealing mechanisms, such as flexible or pressure-energized seals, which significantly reduce leakage and enhance reliability in high-pressure applications. These innovations are not just incremental upgrades; they represent a shift toward more robust solutions that can withstand extreme conditions while minimizing maintenance needs, helping industries comply with stringent environmental and operational standards.

Furthermore, the integration of smart technologies has transformed gate valves into intelligent components within broader industrial systems. Embedded sensors and actuators allow for real-time monitoring of flow rates, pressure differentials, and valve position, facilitating predictive maintenance and reducing downtime. This connectivity, often part of Industrial Internet of Things (IIoT) frameworks, enables seamless data exchange with control systems, optimizing processes and ensuring adherence to efficiency benchmarks that define contemporary industrial operations.

Additionally, advancements in materials science play a crucial role in meeting modern standards, with the use of corrosion-resistant alloys and composite materials extending valve lifespan in harsh environments like chemical processing or offshore oil extraction. This focus on durability not only improves operational longevity but also supports sustainability goals by reducing waste and resource consumption, making advanced gate valves a key enabler for industries striving to balance productivity with environmental responsibility.

When it comes to choosing a UL FM gate valve supplier, the devil is often in the details. Beyond just checking for the required certifications, savvy buyers dig deeper into the supplier's manufacturing processes, quality control measures, and material sourcing. A supplier that offers custom valve solutions tailored to specific operational needs—whether for fire protection systems in high-rise buildings or industrial applications—can provide significant long-term benefits. Look for suppliers who conduct rigorous testing under real-world conditions, as this ensures the valves will perform reliably in emergencies, potentially saving lives and property. Don't just settle for a vendor; opt for a partner with a proven track record in delivering durable, compliant products.

In today's competitive market, selecting the right UL FM gate valve supplier isn't just about ticking boxes—it's about future-proofing your systems. Consider suppliers who invest in research and development, bringing innovations like enhanced corrosion resistance or smoother operation to their valve designs. A standout supplier often provides comprehensive support, including detailed installation guides, maintenance training, and responsive customer service. This holistic approach can reduce downtime, lower total cost of ownership, and ensure seamless integration with your existing infrastructure. By prioritizing suppliers who go above and beyond, you gain not just a product but a strategic advantage in safety and efficiency.

Ultimately, the optimal performance of UL FM gate valves hinges on a supplier's commitment to excellence and adaptability. Seek out suppliers who actively engage with industry standards bodies and continuously update their practices to meet evolving regulations. Customer reviews and case studies can offer valuable insights into a supplier's real-world impact, revealing how their valves perform under pressure. A reliable supplier should also have transparent communication channels, allowing for quick resolution of any issues that arise. Choosing wisely means aligning with a supplier whose values and capabilities mirror your own high standards, ensuring peace of mind and superior system performance for years to come.

One of the key trends shaping industrial valve solutions is the integration of smart technologies, such as IoT sensors and AI-driven monitoring systems. These advancements enable real-time data collection on valve performance, pressure, and temperature, allowing for predictive maintenance and early detection of potential failures. This not only enhances operational efficiency by reducing unplanned downtime but also significantly boosts safety by preventing hazardous leaks and system overpressure. As industries move towards Industry 4.0, these intelligent valves become essential for optimizing resource use and ensuring a safer working environment, blending innovation with practical reliability.

Another emerging trend focuses on the use of advanced materials and eco-friendly designs in valve manufacturing. With growing emphasis on sustainability and regulatory compliance, manufacturers are developing valves from corrosion-resistant alloys, composites, and polymers that offer longer lifespans and reduced maintenance needs. These materials improve efficiency by minimizing energy loss and fluid leakage, while also enhancing safety by withstanding extreme conditions without degradation. Such innovations not only help companies meet stringent environmental standards but also provide cost savings through lower operational risks and extended equipment durability.

Additionally, customization and modular valve systems are gaining traction as industries seek tailored solutions for diverse applications. This trend allows for greater flexibility in adapting valves to specific safety and efficiency requirements, such as in high-pressure or hazardous environments. By offering modular components that can be easily configured and upgraded, manufacturers enable faster implementation and scalability, reducing installation time and errors. This approach not only streamlines operations but also reinforces safety by ensuring precise fit-for-purpose designs, making it easier for industries to stay ahead in a competitive landscape focused on both performance and protection.

FAQ

Top suppliers distinguish themselves through advanced materials like corrosion-resistant alloys, precision engineering for tight shutoffs, and robust testing under UL and FM standards to ensure reliability in high-pressure or hazardous environments.

They incorporate smart technologies such as IoT-enabled monitoring for leak detection, automated fail-safe mechanisms, and customized designs that reduce human error and prevent accidents, ensuring compliance with strict safety regulations.

Industries like oil and gas, chemical processing, power generation, and water treatment depend on them due to their ability to handle extreme temperatures, pressures, and corrosive fluids while maintaining operational integrity and safety certifications.

UL certification verifies electrical and fire safety, while FM focuses on property loss prevention; together, they assure that valves meet rigorous performance and durability standards, crucial for minimizing risks in critical infrastructures.

Emerging trends include the integration of AI for predictive maintenance, development of eco-friendly materials to reduce environmental impact, and modular designs that allow for easier upgrades and adaptability to changing industrial needs.

They implement rigorous quality control processes, such as lifecycle testing under simulated operational conditions, use of durable components like stainless steel seats, and offer comprehensive warranties and after-sales support to maintain performance over decades.

Key considerations include the supplier's track record with similar applications, customization options for unique system requirements, availability of technical support, and adherence to international standards beyond UL and FM, such as API or ISO certifications.

Conclusion

The industrial landscape increasingly prioritizes safety and reliability in flow control, particularly in hazardous environments; top UL FM gate valve suppliers address this need by specializing in innovative solutions that enhance system integrity and operational efficiency. Leading manufacturers focus on rigorous UL FM certifications to ensure valves meet stringent standards for fire safety and performance, thereby providing crucial protection in critical systems where valve failure could lead to catastrophic outcomes. Key suppliers offer advanced gate valve technologies, such as improved sealing mechanisms and corrosion-resistant materials, which help prevent leaks and withstand harsh conditions, contributing to the overall durability and effectiveness of industrial infrastructures.

Selecting the right UL FM gate valve supplier involves evaluating factors like technical expertise, product range, and compliance with modern industrial standards, ensuring optimal performance tailored to specific applications. Future trends suggest a growing emphasis on smart valve solutions that integrate IoT for real-time monitoring and predictive maintenance, aiming to boost both safety and efficiency in industrial operations. As these innovations evolve, suppliers continue to adapt, offering customized flow control systems that not only meet current demands but also anticipate emerging challenges, driving the industry toward more resilient and sustainable practices.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com