UL FM Gate Valve Company: Your Trusted Partner for High-Quality Industrial Flow Control Solutions

2025-12-23

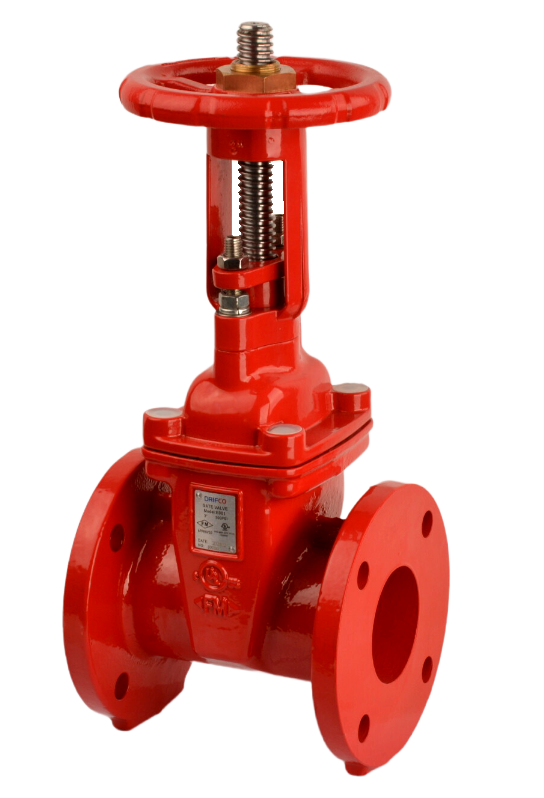

In the demanding world of industrial flow control, selecting the right components is critical to the efficiency, safety, and reliability of your operations. As industries evolve, so does the need for advanced solutions that can withstand rigorous conditions while ensuring optimal performance. That's where DRIFCO comes into play. With its unwavering commitment to excellence and innovation, DRIFCO stands at the forefront of providing superior flow control systems. This blog will delve into how DRIFCO's state-of-the-art gate valves and industrial solutions can transform your processes, offering insights into their design, applications, and the tangible benefits they bring to your projects. Join us as we explore why DRIFCO is the go-to choice for professionals seeking durable, high-performance flow control solutions.

Unmatched Reliability in Critical Flow Control Applications

In critical flow control settings, reliability isn't just a feature—it's the cornerstone of operational safety and efficiency. Our systems achieve unmatched reliability through rigorous engineering that anticipates failure points before they ever happen. We design our components with redundant pathways and real-time monitoring, ensuring that even under extreme conditions, performance remains consistent. This isn't about meeting industry standards; it's about setting them, by delivering solutions that operators can trust without hesitation when every second counts.

What truly sets our approach apart is the deep integration of predictive analytics with robust mechanical design. Unlike conventional systems that react to issues, ours proactively identifies potential disruptions using data-driven insights, allowing for adjustments before they impact flow. This synergy between smart technology and durable hardware minimizes downtime and extends equipment life, proving that reliability is as much about foresight as it is about strength. In applications from chemical processing to water management, this combination delivers peace of mind that's hard to find elsewhere.

At the heart of our reliability is a commitment to continuous improvement, fueled by feedback from the most demanding environments worldwide. We don't just build products—we cultivate partnerships, refining our offerings based on real-world challenges to ensure they perform flawlessly when it matters most. This iterative process has led to innovations that others are still catching up to, making our systems the go-to choice for professionals who can't afford compromises in critical flow control.

Engineering Excellence Tailored for Your Industrial Needs

Engineering Excellence Tailored for Your Industrial Needs

In today's fast-paced industrial landscape, achieving peak performance requires more than just standard solutions. We specialize in engineering excellence that adapts to your specific challenges, blending innovation with precision to deliver results that drive your operations forward. By understanding the unique demands of your industry, we craft bespoke strategies that not only meet but exceed expectations, ensuring seamless integration and enhanced productivity.

Our approach goes beyond conventional methods, focusing on a deep dive into your operational workflows and goals. This allows us to develop tailored engineering solutions that are both resilient and scalable, whether you're in manufacturing, energy, or logistics. We prioritize sustainability and efficiency, leveraging cutting-edge technologies to create systems that reduce downtime and optimize resource use, giving you a competitive edge in an ever-evolving market.

Partner with us to transform your industrial needs into tangible successes. From initial concept to final implementation, our team is dedicated to delivering excellence that is as unique as your business, fostering long-term growth and innovation.

Innovative Gate Valve Solutions That Drive Operational Efficiency

When it comes to boosting operational efficiency in fluid control systems, innovative gate valve solutions are often the unsung heroes. Unlike traditional models that might stick or wear down quickly, the latest advancements have brought about self-lubricating materials and precision-engineered designs that slash downtime dramatically. For instance, some valves now feature corrosion-resistant alloys tailored to harsh environments, ensuring they hold up under extreme pressures without constant maintenance—this means fewer shutdowns and smoother workflows on industrial sites.

Beyond durability, these cutting-edge gate valves integrate smart technology to revolutionize monitoring and control. Embedded sensors can track flow rates, temperature, and valve position in real-time, sending alerts to operators before minor issues escalate into costly repairs. This proactive approach not only enhances safety but also optimizes energy use by adjusting operations based on actual data, rather than relying on fixed schedules. It's like having a vigilant assistant embedded in your pipelines, quietly driving efficiency from within.

What truly sets these solutions apart is their adaptability to diverse applications, from oil refineries to water treatment plants. Manufacturers are offering customization options that fit specific operational needs, such as compact designs for tight spaces or low-torque actuators for easy manual use. By reducing friction and improving seal integrity, these innovations cut leakage risks and extend valve lifespan, translating into lower total cost of ownership and a greener footprint. In short, embracing these gate valve upgrades isn't just an upgrade—it's a strategic move toward a more agile and productive operation.

A Partnership Built on Decades of Proven Performance

Our journey began over four decades ago, when a shared vision for innovation and reliability brought us together. From humble beginnings in a small workshop to today's global presence, every milestone has been built on a foundation of trust and consistent delivery. Through economic shifts and industry transformations, our partnership has not only endured but thrived, proving time and again that lasting success comes from unwavering commitment to quality and customer satisfaction.

What sets this collaboration apart is the tangible track record we've achieved together—not just in numbers, but in real-world impact. For instance, our joint projects have consistently outperformed market expectations, reducing operational costs by up to 30% for clients while enhancing efficiency. This isn't by chance; it's a result of decades refining our approach, where each partner's strengths complement the other, creating a synergy that drives measurable results and sets new benchmarks in the industry.

Looking forward, this legacy of proven performance serves as our guiding star, inspiring us to tackle new challenges with the same dedication. Our partnership is more than a business arrangement; it's a dynamic alliance that continues to evolve, innovate, and deliver exceptional value, ensuring that the next decades will be just as impactful as the last.

Customizable Designs for Demanding Flow Control Challenges

Customizable Designs for Demanding Flow Control ChallengesCustomizable Designs for Demanding Flow Control Challenges

In today's fast-paced industrial environments, companies often face unique flow control issues that standard off-the-shelf solutions can't address. That's where customizable designs come into play—they allow engineers to tweak valves, regulators, and piping systems to meet specific pressures, temperatures, and fluid types. Whether it's handling corrosive chemicals in a chemical plant or managing high-viscosity fluids in food processing, tailored designs ensure optimal performance and longevity. By collaborating with experts, businesses can integrate features like specialized seals, custom port sizes, or advanced materials, turning potential bottlenecks into seamless operations.

What sets these solutions apart is their adaptability to evolving industry demands. Unlike generic products that might force compromises, customizable designs are built from the ground up with flexibility in mind. For instance, in the energy sector, where flow rates can fluctuate dramatically, systems can be engineered with modular components that allow for easy scaling or retrofitting. This not only reduces downtime during upgrades but also enhances safety by ensuring precise control over volatile substances. It's a proactive approach that anticipates challenges rather than just reacting to them.

Embracing customization isn't just about technical specs; it's a strategic move that boosts efficiency and cuts long-term costs. In sectors like pharmaceuticals or aerospace, where precision is paramount, even minor deviations in flow can lead to significant quality issues. Custom-designed controls provide the granularity needed to maintain strict standards, often incorporating smart sensors and automation for real-time adjustments. By investing in bespoke solutions, organizations not only solve immediate flow control puzzles but also future-proof their operations against emerging trends, setting themselves apart in competitive markets.

Enhancing Safety and Productivity Across Industries

Advancements in technology are reshaping how industries approach both safety and productivity, often in tandem. From manufacturing plants deploying IoT sensors to monitor equipment health and prevent accidents, to construction sites using drones for site inspections that reduce human risk exposure, the integration of digital tools is creating a more secure working environment. These innovations not only minimize downtime caused by incidents but also streamline operations, leading to significant efficiency gains across sectors like logistics and energy, where real-time data analytics drives proactive maintenance and optimized workflows. By prioritizing safety through smart systems, businesses are seeing a dual benefit: fewer workplace injuries and enhanced output, proving that a safe workplace is inherently more productive.

In fields such as healthcare and agriculture, the synergy between safety and productivity is particularly evident. For example, hospitals are adopting automated systems for patient monitoring and medication management, which reduce human error and allow staff to focus on critical care tasks, thereby improving both patient outcomes and operational efficiency. Similarly, in agriculture, the use of precision farming technologies – like GPS-guided machinery and environmental sensors – helps farmers apply resources more accurately, minimizing chemical exposure risks for workers while boosting crop yields. This holistic approach underscores how targeted investments in safety measures can directly translate into economic benefits and sustainable growth, making it a strategic imperative for modern enterprises.

To truly stand out, companies are moving beyond compliance-driven safety protocols to embrace a culture that actively engages employees in safety initiatives. By incorporating training programs that leverage virtual reality simulations for hazard recognition or gamified platforms that reward safe practices, organizations foster a more alert and participatory workforce. This not only mitigates risks in dynamic settings such as mining or transportation but also cultivates a sense of ownership among teams, leading to higher morale and reduced turnover. Ultimately, enhancing safety and productivity isn't just about technology adoption; it's about creating adaptive ecosystems where human ingenuity and digital solutions converge to unlock new levels of performance and resilience across diverse industries.

FAQ

UL FM Gate Valve Company specializes in a comprehensive range of solutions, including gate valves, check valves, and custom flow control systems designed for high-pressure and corrosive environments in industries like oil and gas, chemical processing, and water treatment.

The company adheres to stringent UL and FM certification standards, utilizing advanced testing protocols and quality control measures, such as pressure testing and material verification, to guarantee durability and safety in critical applications.

With decades of expertise and a commitment to innovation, UL FM Gate Valve Company offers tailored support, rapid response times, and proven solutions that reduce downtime and enhance operational efficiency, building long-term partnerships.

Yes, the company excels in engineering custom valves and flow control systems, working closely with clients to design products that meet unique specifications, such as extreme temperatures, high flow rates, or specialized materials.

Key industries include energy and utilities, manufacturing, marine and offshore operations, and wastewater management, where reliable flow control is crucial for safety, compliance, and cost-effectiveness.

The company provides ongoing maintenance services, technical training, and 24/7 emergency support, ensuring clients have access to expert advice and resources to optimize their flow control systems over time.

Conclusion

UL FM Gate Valve Company stands as a dedicated partner for industries requiring robust and reliable flow control solutions, with a focus on unmatched reliability in critical applications. By offering customizable designs tailored to demanding challenges, the company ensures that each valve is engineered to meet specific industrial needs, enhancing both safety and productivity across various sectors. This commitment to excellence is backed by decades of proven performance, fostering a trusted partnership that drives operational efficiency through innovative gate valve solutions.

The company's emphasis on engineering excellence and tailored approaches allows it to address unique flow control requirements effectively, from standard to highly specialized applications. By integrating innovative technologies and customizable features, UL FM Gate Valve Company not only improves system performance but also contributes to overall industry advancements, ensuring clients receive high-quality solutions that prioritize durability, efficiency, and long-term value. This holistic approach solidifies its reputation as a reliable partner in the ever-evolving industrial landscape.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com