Crafting Excellence: The Art of Zinc Die Casting Moulds

2023-10-17

Introduction

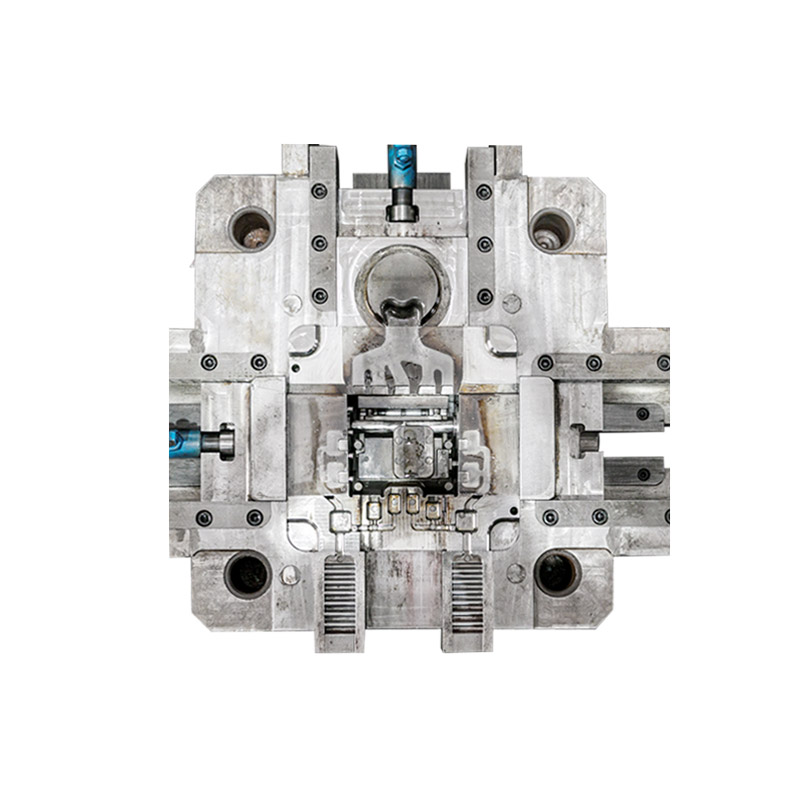

In the world of manufacturing, precision and durability are essential qualities for success. Zinc die casting molds are a crucial part of the process, often working behind the scenes to create intricate and high-quality products. These molds enable manufacturers to craft everything from automotive parts to consumer electronics with precision and efficiency. In this blog, we will delve into the art and science of zinc die casting molds, exploring their importance, construction, and the industries that rely on them.

The Foundation of Excellence: Zinc Die Casting Moulds

What is Zinc Die Casting?

Zinc die casting is a manufacturing process that involves injecting molten zinc alloy into a mold to create a specific shape or component. It is renowned for its exceptional precision, high production rates, and ability to produce complex, detailed parts with remarkable consistency.

The Role of Zinc Die Casting Moulds

Zinc die casting molds are the heart of this process. They serve as the template into which the molten zinc is injected, defining the shape and design of the final product. Here's why they are indispensable:

1. Precision and Reproducibility: Molds ensure that each cast product is consistent and precise. This is particularly critical for industries where tight tolerances and exact specifications are required.

2. Complex Geometries: Zinc die casting molds can create parts with intricate designs, including undercuts, fine details, and thin walls, which would be challenging or impossible to achieve with other manufacturing methods.

3. Efficiency: These molds enable rapid production, making zinc die casting an excellent choice for high-volume manufacturing. The cycle times are relatively short, resulting in cost-effective production.

Construction of Zinc Die Casting Moulds

Creating a high-quality zinc die casting mold requires expertise, precision, and attention to detail. The key steps in their construction include:

1. Design: Mold designers meticulously plan every aspect of the mold, considering factors such as part geometry, cooling channels, and ejection mechanisms.

2. Machining: Skilled machinists use CNC (Computer Numerical Control) machines to carve the mold cavity and core from hardened steel or other materials. This process demands utmost precision.

3. Surface Finish: The quality of the mold's surface finish is crucial as it directly impacts the final product's appearance. The mold's surfaces are polished to minimize defects.

4. Heat Treatment: Heat treatment processes are applied to enhance the mold's hardness and durability, ensuring it can withstand the extreme temperatures and pressures of zinc die casting.

5. Assembly: Various components, such as ejector pins, slides, and cooling systems, are assembled into the mold to ensure it functions smoothly.

Industries that Rely on Zinc Die Casting molds

Zinc die casting molds find applications across a wide range of industries, including:

1. Automotive: Zinc die casting is used to create components like engine parts, transmission housings, and brackets, contributing to lightweight, durable, and fuel-efficient vehicles.

2. Consumer Electronics: Molds are employed to manufacture intricate parts for smartphones, laptops, and other electronic devices, maintaining their sleek and functional designs.

3. Aerospace: The aerospace industry relies on zinc die casting to produce lightweight, high-strength components for aircraft and spacecraft.

4. Medical Devices: Zinc die casting is used for the production of medical equipment and devices, ensuring precision, durability, and reliability.

5. Industrial Equipment: Manufacturers in various industries utilize zinc die casting molds to create critical components for machinery and equipment.

Conclusion

Zinc die casting molds are the unsung heroes behind the scenes of countless products that we use every day. Their precision, versatility, and efficiency make them an indispensable tool in modern manufacturing. As technology continues to advance, these molds will play an even more pivotal role in crafting high-quality, intricate components across a wide range of industries. The art of creating zinc die casting molds exemplifies the marriage of craftsmanship and technology that underpins the world of manufacturing excellence.