Plastic Crate Injection Moulding Machine: Efficient and Reliable Solution for Crate Production

2023-10-17

Introduction

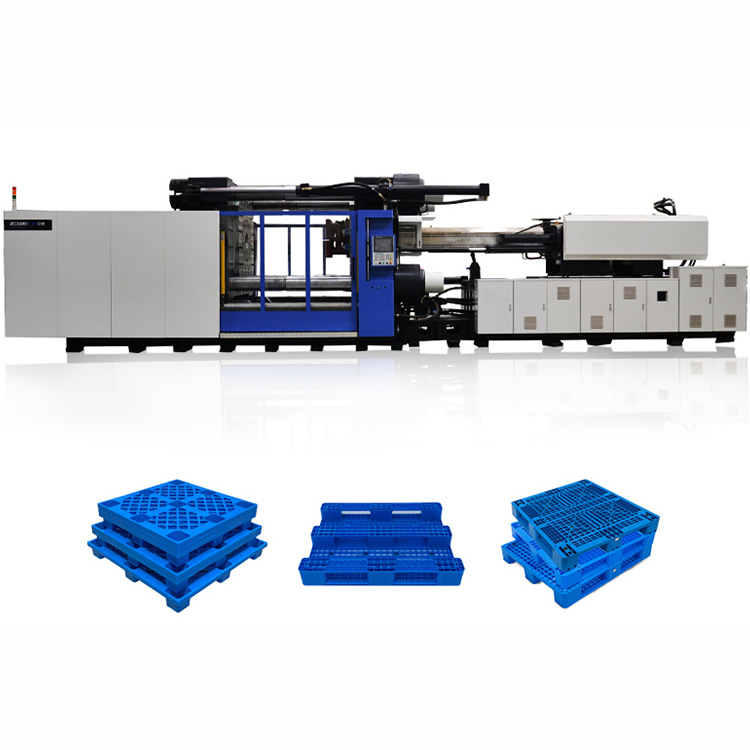

In industries that require efficient storage and transportation solutions, plastic crates have become indispensable. The Plastic Crate Injection Moulding Machine offers a reliable and cost-effective method for producing high-quality plastic crates. This advanced machine utilizes the injection moulding process to manufacture crates with precision, speed, and consistency. In this blog post, we will explore the features, benefits, and applications of the Plastic Crate Injection Moulding Machine, highlighting its significance in crate production.

1. Understanding Plastic Crate Injection Moulding

Plastic crate injection moulding is a manufacturing process that involves injecting molten plastic into a mould cavity to create plastic crates. The process begins with the preparation of plastic resin, which is melted and injected into the mould under high pressure. Once the plastic cools and solidifies, the mould opens, and the finished crate is ejected. Plastic crate injection moulding allows for the production of crates with complex designs, precise dimensions, and consistent quality.

2. Efficient and High-Speed Production

The Plastic Crate Injection Moulding Machine enables efficient and high-speed production of plastic crates. The machine is equipped with advanced hydraulic or electric systems that ensure precise control over the injection process, allowing for rapid and accurate mould filling. With the ability to produce multiple crates in each cycle, the machine optimizes production output, reducing manufacturing time and increasing overall efficiency.

3. Versatility and Customization

The Plastic Crate Injection Moulding Machine offers versatility in crate production, accommodating various crate sizes, designs, and configurations. The machine's adjustable moulding parameters allow for customization, enabling manufacturers to produce crates that meet specific requirements and market demands. Whether it's stackable crates, collapsible crates, or crates with specific features like dividers or handles, the machine can adapt to different design specifications.

4. Consistent Quality and Durability

Plastic crate injection moulding ensures consistent quality and durability in the produced crates. The process allows for precise control over the material distribution and cooling, resulting in uniform wall thickness, strength, and structural integrity. The high-quality plastic used in the injection moulding process offers excellent impact resistance, corrosion resistance, and longevity. The consistent quality and durability of the crates provide reliable storage and transportation solutions for various industries.

5. Cost-Effectiveness and Resource Efficiency

The Plastic Crate Injection Moulding Machine offers cost-effectiveness and resource efficiency in crate production. The automated nature of the machine reduces labor costs and minimizes the risk of human errors. The precise injection process minimizes material waste by optimizing material usage. Additionally, plastic crates produced through injection moulding are lightweight, reducing transportation costs and carbon emissions. The cost-effectiveness and resource efficiency of the machine make it a sustainable choice for crate manufacturing.

6. Applications in Diverse Industries

Plastic crate injection moulding has applications in diverse industries that require efficient storage and transportation solutions. These industries include logistics, warehousing, agriculture, food and beverage, automotive, retail, and more. Plastic crates produced by the injection moulding process provide a reliable and hygienic solution for handling and transporting a wide range of goods, including fruits and vegetables, bottles, automotive components, electronic devices, and retail merchandise.

Conclusion

The Plastic Crate Injection Moulding Machine offers a reliable and efficient solution for producing high-quality plastic crates. With its high-speed production, versatility, and customization options, the machine meets the specific requirements of diverse industries. The consistent quality, durability, and cost-effectiveness of the plastic crates produced through injection moulding make them an ideal choice for storage and transportation applications. As industries continue to demand efficient and reliable solutions, the Plastic Crate Injection Moulding Machine remains a valuable asset, contributing to the seamless flow of goods and optimizing operational efficiency in various sectors.